Manufacturing engineering, BS

Our hands-on bachelor’s degree in manufacturing engineering will provide you with a venue to design cost-effective and sustainable products and processes towards the future of manufacturing.

Program description

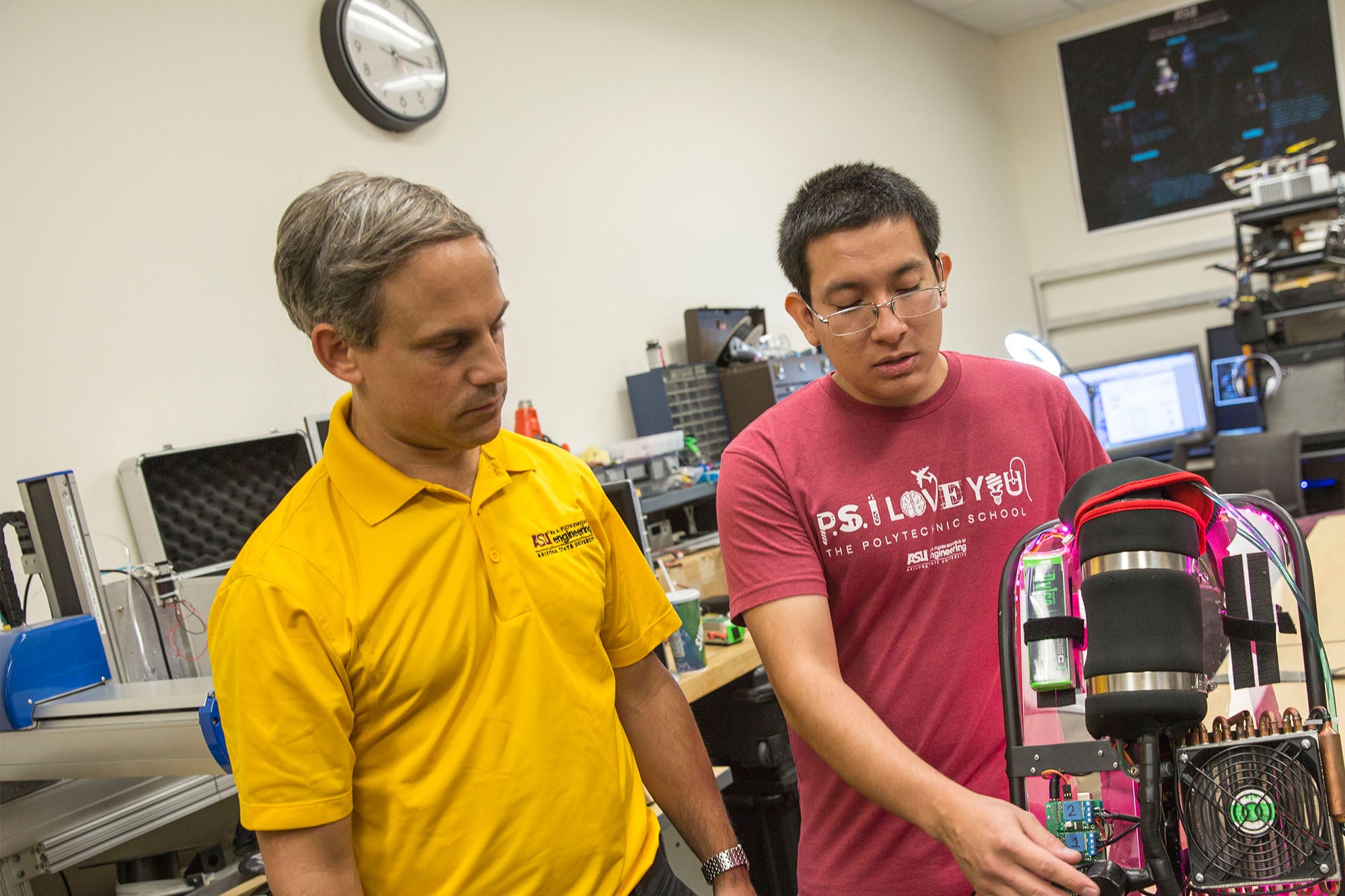

The project-based, hands-on curriculum and the outstanding fabrication facilities equip graduates to excel as manufacturing engineers as the manufacturing industry makes a dramatic transformation into a future globalized supply network. The team-based learning environment teaches students to find innovative ways to integrate products and services in this ever-changing, fast-paced and complex field.

Students will become key team members who will enable the design of new processes for making such varied products as airplanes, surgical instrument, toys and foodstuffs that meet customer needs, and doing so at the best price and in the most sustainable way while adhering to quality and functionality standards.

Career outlook

Graduates typically work as manufacturing engineers in a variety of companies, large and small. They are often members of design and development teams, cooperating with other people in and outside of their company. Career employment opportunities include direct manufacturing support, manufacturing management and quality control and assurance in large and midsized, established manufacturing companies.

Due to a strong, broad and practical engineering skill set, graduates are also highly valuable in small companies or new start-up companies. Our graduates are well placed and command top salaries in their engineering careers.

Example salary range: $88,000-$150,000/year.

Required courses (major map)

Additional program fee: Yes.

Technical electives

Technical electives can be selected from the list below:

- EGR 370 Welding Survey

- EGR 380 Advanced Computer Aided Design and Drafting (CADD) and Solid Modeling

- MFG 472 Additive Manufacturing

- MFG 485 Engineering Internship

- MFG 486 CNC Computer Programming

- MFG 494 Special Topics

Application deadlines

December 1 Spring semester (January)

March 1 Summer session 1 (June) and Summer session 2 (July)

May 1 Fall semester (August)

These are the priority application deadlines for admission and merit-based scholarship consideration. Late applicants will be considered for university admission and financial aid, but programs with higher admission standards will give priority consideration to applications submitted by these dates. Please view important dates on the academic calendar.

Accelerated master’s option

Finish two degrees faster by combining advanced undergraduate and graduate coursework during your senior year as part of the accelerated master’s program.

WUE eligible

This major is eligible for the Western Undergraduate Exchange (WUE) program. Students from Western states who select this major and campus may be eligible for reduced tuition.

More information about the WUE program.

Accreditation

The manufacturing engineering, BS program is accredited by the Engineering Accreditation Commission of ABET, http://www.abet.org. Student enrollment and graduation data are available at https://engineering.asu.edu/enrollment/.

Professional Licensure

ASU programs that may lead to professional licensure or certification are intended to prepare students for potential licensure or certification in Arizona. Completion of an ASU program may not meet educational requirements for licensure or certification in another state. For more information, students should visit the ASU professional licensure webpage.

- In their first few years after graduating, our alumni will have chosen from a broad range of career paths including industry, government, nonprofit, entrepreneurship, and graduate and professional education.

- In their first few years after graduating, our alumni will progress in their chosen career on a path towards increased technical and/or supervisory responsibility.

- In their first few years after graduating, our alumni will contribute to solutions of complex problems by drawing from an integrated multi-disciplinary engineering education.

- Engineering Problem Solving (ABET 1): an ability to identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics.

- User Centered Design (ABET 2): an ability to apply engineering design to produce solutions that meet specified needs with consideration of public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors.

- Communications (ABET 3): an ability to communicate effectively with a range of audiences.

- Professional Context (ABET 4): an ability to recognize ethical and professional responsibilities in engineering situations and make informed judgments, which must consider the impact of engineering solutions in global, economic, environmental, and societal contexts.

- Multidisciplinary Teamwork (ABET 5): an ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives.

- Critical Thinking & Decision Making (ABET 6): an ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions.

- Strategic Learning (ABET 7): an ability to acquire and apply new knowledge as needed, using appropriate learning strategies.

Students will become proficient in the following areas:

- materials and manufacturing processes: ability to design manufacturing processes that result in products that meet specific material and other requirements;

- process, assembly and product engineering: ability to design products and the equipment, tooling and environment necessary for their manufacture;

- manufacturing competitiveness: ability to create competitive advantage through manufacturing planning, strategy, quality and control;

- manufacturing systems design: ability to analyze, synthesize and control manufacturing operations using statistical methods; and

- manufacturing laboratory or facility experience: ability to measure manufacturing process variables and develop technical inferences about the process.